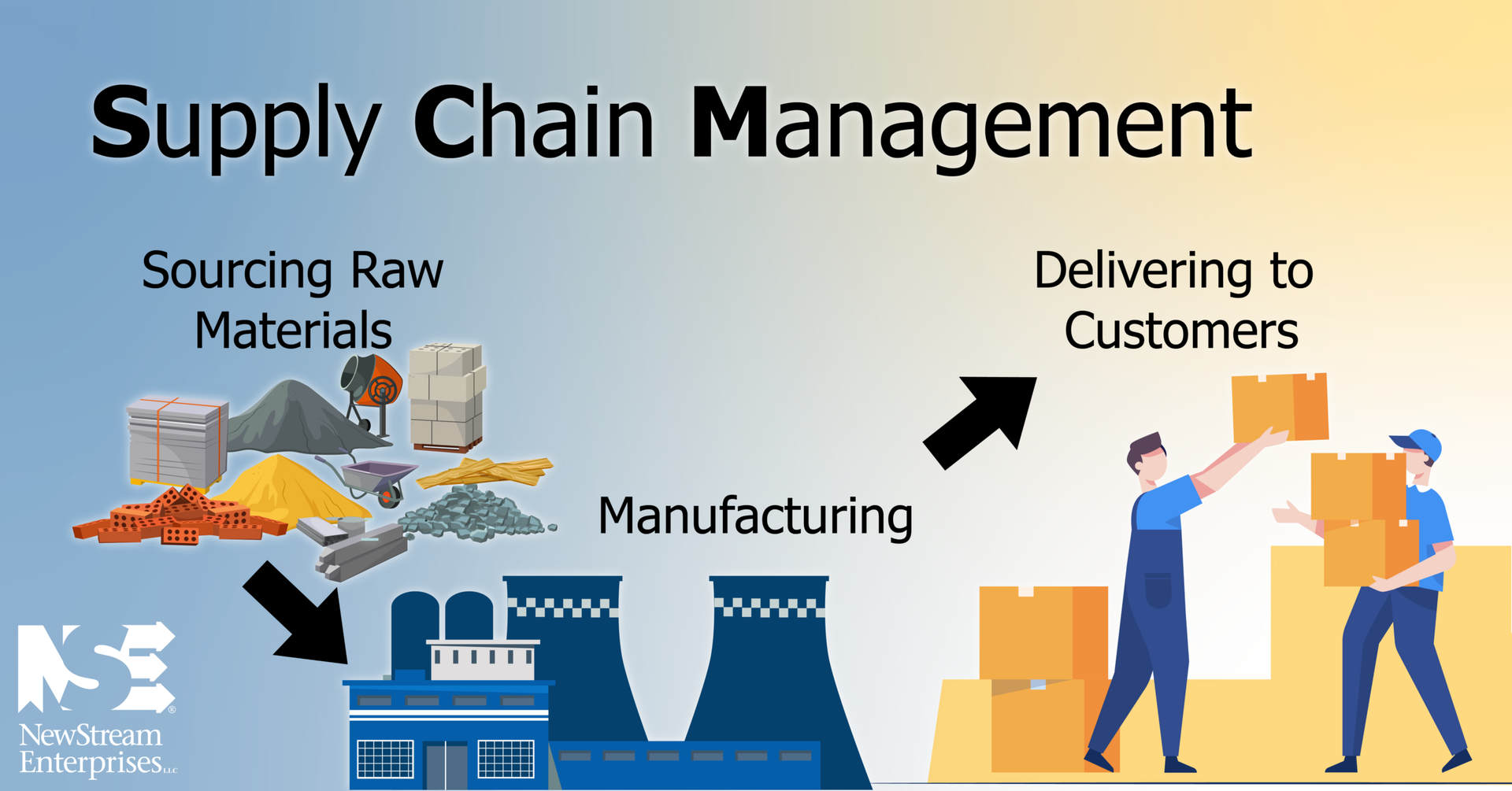

How Does Supply Chain Management Work?

Supply chain management is the act of coordinating various efforts to develop and implement certain supply chains that are as cost effective and efficient as possible. The supply chain can cover everything from production to product development and even works to help control or link production, shipments, and distribution in an attempt to cut excess costs and help deliver products faster.

5 Parts of a Supply Chain Management Plan

The supply chain management process typically starts with planning which helps match supply with the customer and manufacturing demands. Your company must use supply chain forecasting to help predict the future needs of supply chain so that your business can act accordingly such as having enough raw materials, having the capacity for equipment, and being able to staff properly during busy times.

Source

In supply chain management, keeping a strong and trustworthy relationship with your suppliers is crucial. This is important as sourcing raw materials requires working with your vendors to keep a consistent flow of these materials throughout the manufacturing process. With a good relationship your company may be able to plan and work with your suppliers to help source necessary goods in advance, however, keep in mind that different industries can have different sourcing requirements.

Manufacture

The heart of the supply chain process is manufacturing; when your company takes raw materials and transforms them into a new product by using machinery, labor, and external forces. Typically, the manufacturing process is divided into sub-tasks such as assembly, testing inspection, and packaging and companies must be mindful of waste and other controllable factors that may get these processes off track. While the final product is one of the most important goals of the manufacturing process, it is not the final stage of supply chain management.

Deliver

Once products have been completed and sales have been finalized, it is now the next step in the supply chain management process; getting these products to the customer. Often, the distribution process acts as a brand image contributor for companies as their customer has not yet interacted with their product. Having a strong supply chain management process allows your company to have sturdy logistic capabilities and delivery channels to ensure products are delivered on time, safely, and cost effective.

Return

After your supply chain has gone through the first four processes, the next step is to support the product and customer with any potential returns. Though it can feel defeating receiving returns, it is still important that your company ensures the capabilities to receive returned product and assign the correct refunds to your customers. Whether your company is performing a product recall or your customer is just dissatisfied with the product, the transaction must be remedied.

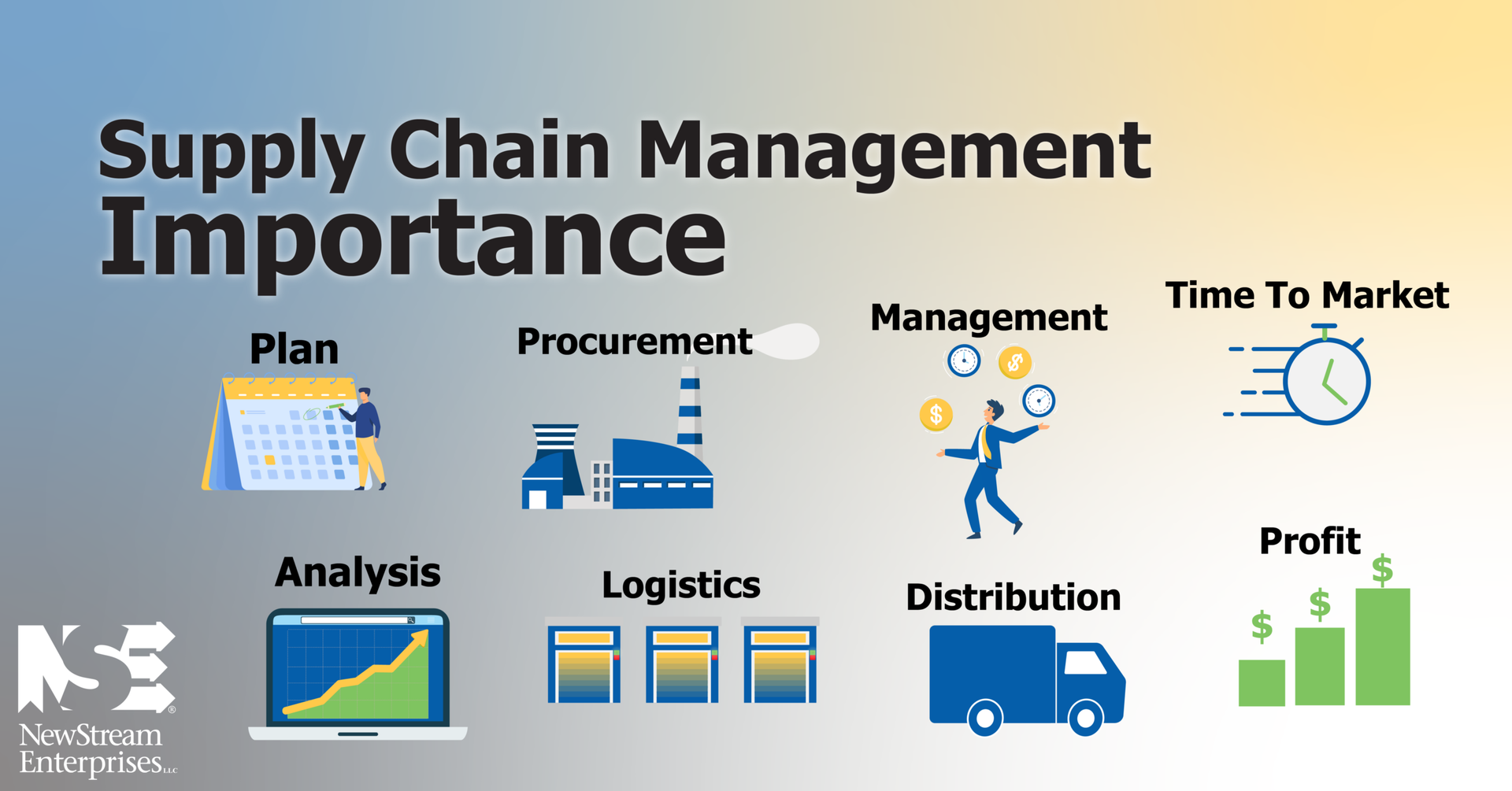

Why is Supply Chain Management Important?

Proper supply chain management is crucial to the success of any business as it can help you achieve your goals. For example, having control over your manufacturing process can help to improve product quality, reduce risk of recalls and lawsuits while simultaneously helping build a strong consumer brand. Your business will also have control over shipping procedures which can help improve customer service, ultimately avoiding costly shortages or periods of inventory oversupply. Overall, supply chain management is important as it provides several opportunities for companies to improve their profit margins.

SCM can be complex but it doesn’t have to be when partnering with the proper 3PL. As a reputable 3PL with over 30 years of comprehensive SCM, NewStream is equipped with the proper knowledge and technology your business needs to help you have a better understanding of the supply chain so that you can set yourself apart from the rest.

Ready to partner with a 3PL? Let’a chat, our experts are ready to help!