Assembly & Sub-Assembly

Original equipment manufacturers (OEM) encounter several hurdles within their market that may drive them toward outsourcing assembly work. First, cost reduction remains a top priority. By opting for contract assembly, OEMs sidestep the fixed costs associated with maintaining their own manufacturing facilities and equipment. Second, quality and efficiency are critical. Specialized providers can often deliver better quality and streamline production processes. Lastly, OEMs may face bandwidth constraints, lacking the internal capacity to handle all aspects of production in-house as overall demand with their market is on the rise.

NewStream brings more to the table with their contract assembly and sub-assembly services than just cost reduction, quality, and bandwidth constraints. As a reliable value-added servicer (VAS) provider, our clients benefit from:

- Expertise: Our employee-owners have over 34 years of experience in assembly and sub-assembly for on- and off-highway OEMs. We specialize in assembly and sub-assembly, ensuring high-quality work.

- Scalability: We have a track record of scaling to the specific need of our customers. NewStream can quickly adjust production capacity based on OEM needs to OEM specifications.

- Supply Chain Integration: Seamless integration of assembly processes enhances efficiency and reduces lead times. We start with the end in mind – your customers’ user experience.

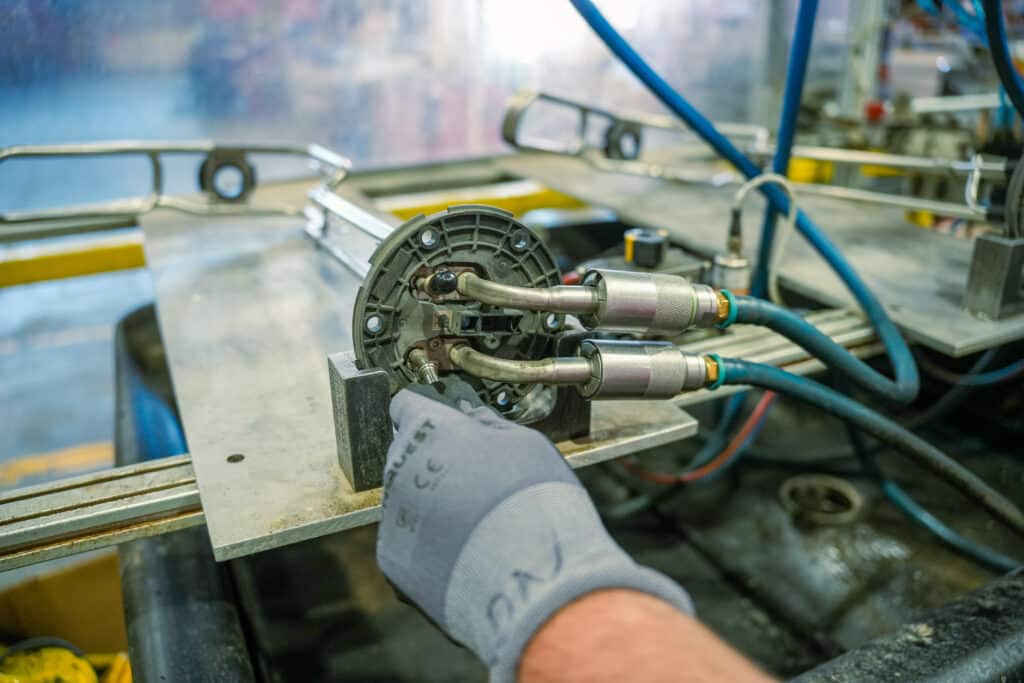

- High Focus on Quality: At NewStream, our skilled assembly-lined team uses advanced error-proofing assembly technology to ensure that parts and products are available for your production line or distribution channels.

- Add-on Services: Our product assembly services can include pack-out services and kit assembly services to round out your product offer in the marketplace.

To optimize logistics, packaging and assembly should be performed in relatively close proximity to your markets. NewStream Enterprises, LLC is strategically located in the central US with the ability to quickly and efficiently ship to locations nationwide. Our warehouse and assembly facility is perfectly positioned to assist your organization at its current site and at any US locations you choose to open in the future. Partnering with NewStream gives you a competitive advantage wherever you decide to do business.

Understanding the value of uptime and customer satisfaction, our teams are positioned to turn customer issues into revenues. The QLS Sensor Assembly project is a great example of our resilience and flexibility. In this project, we worked with our truck and engine manufacturing client to overcome a part shortage problem that caused a major production shortfall. Within the first three days of the program, our team shipped the first unit. Our assembly crew was producing 600 sensors per day after only 7 weeks, 180 more than the customers had demanded.

At NewStream, we are confident that our exceptional teamwork, flexibility, and reliability will aids in keeping up with the unpredictable current demand, alleviating your stress and helping you love your supply chain. Let us handle your assembly and subassembly details today and be ready to become the leader in the aftermarket.

Get an Assembly Quote

"*" indicates required fields